Melchior MB&F’s robot buddy table clock by L’Epée 1839

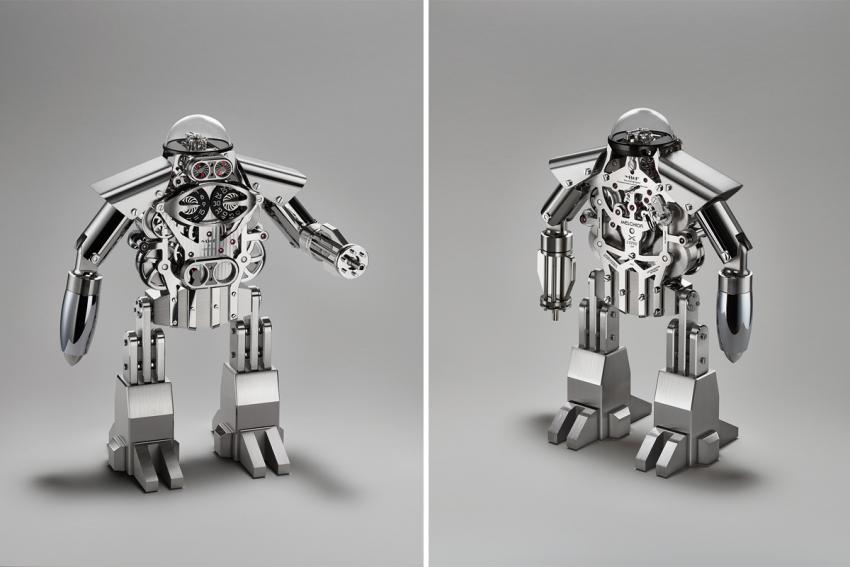

Melchior was one of the stars of Baselworld 2015. The almost one foot high robot is part of MB&F’s Anniversary Pieces, a collection that celebrates a decade of existence of Maximilian Büsser & Friends, one of the most exiting horological laboratories of today.

Conceived and developed by concept lab MB&F, and engineered and crafted by L’Epée 1839 – Switzerland’s only specialised high-end clock manufacture – Melchior is the result of Maximilian Büsser’s childhood dream to have a robot friend:

“As a 10-year-old fan of Star Wars, I knew Luke Skywalker could never have prevailed had it not been for droids like R2-D2 – a loyal, resourceful and brave robot who was always saving his friends. As an only child, I imagined having my own robot companion… Melchior makes that childhood fantasy a reality.”

Büsser developed the concept with designer Xin Wang, selecting a high-end L’Epée clock movement and reimagining it as the mechanical head and torso of a robot.

Melchior comprises no fewer than 480 components — each one machined and finished at L’Epée’s Swiss atelier — with 334 components being used for the movement, while another 146 pieces comprise Melchior’s bodywork and armour.

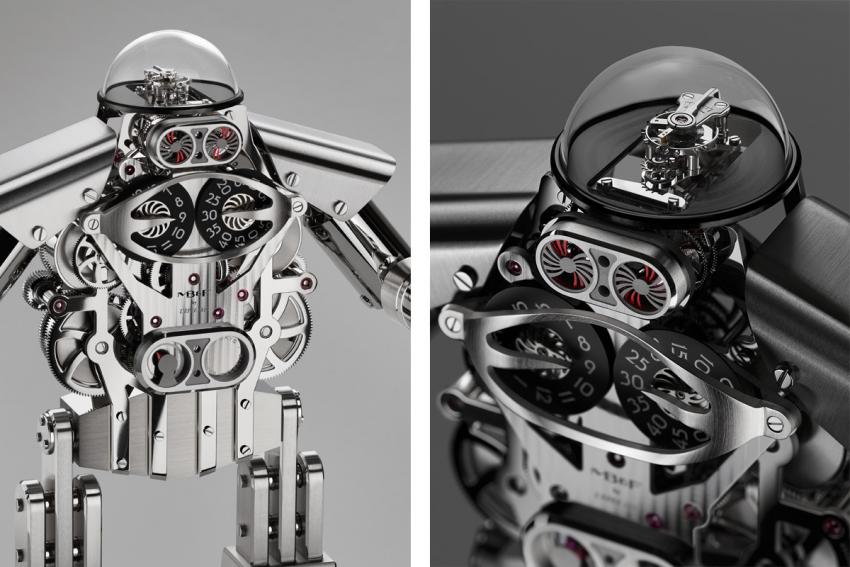

The winding/time-setting key clips into Melchior’s left elbow joint socket. It is held by a small magnet strong enough to hold the key, but not so powerful as to affect the function of the movement. The key boasts a double-depth square socket that neatly fits over both of the square pegs on the back of Melchior. One of the pegs is for winding the movement, the other for time-setting.

Working from MB&F’s design, L’Epée diligently developed the various bodywork and armour components, carefully choosing materials according to the properties required. Where precision was critical – Melchior’s kinetic parts or his precision rocket launcher, for instance – plated brass was selected. His armour on the other hand is crafted mainly in stainless steel, providing optimal resistance to withstand any enemy attacks. And for the finishing touch, L’Epée have applied a range of eye-catching finishes to Melchior’s bodywork – including anglage, mirror polishing, satin finishing, circular satin finishing, sand-blasting and polishing.

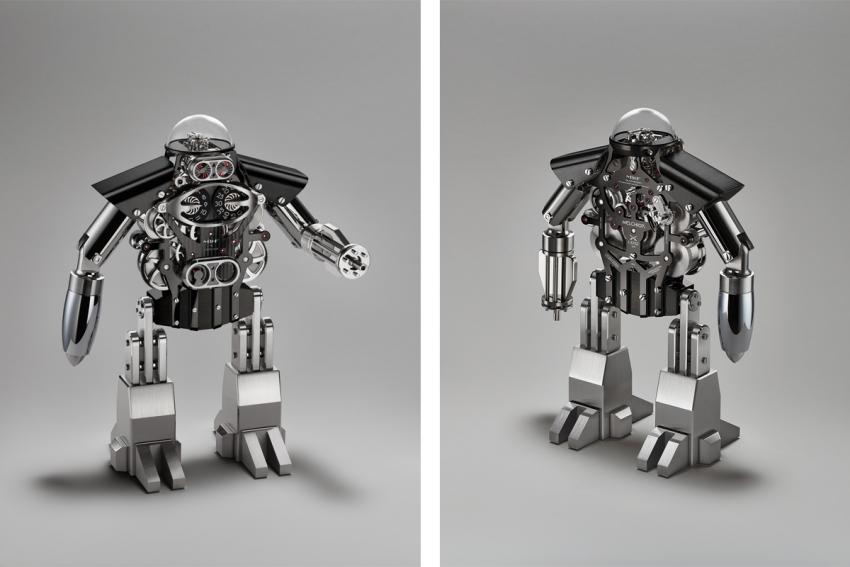

To create Melchior’s highly visible movement, L’Epée developed a completely new skeletonised mainplate, in palladium-plated brass, which sandwiches the movement mechanism, also in palladium-plated brass. This mainplate – which forms the ribcage, breastplate, cheekbones and backbones of the robot – is black PVD-treated for the ‘darkand-light’ edition of Melchior.

For clear reading of the hour, L’Epée developed a ‘slow’ jumping hour. This in-house complication sees the hour disc remain static for 55 minutes, then start to turn five minutes before the new hour so that the change of hour is smooth and subtle.

The movement regulator features an Incabloc shock protection system, which minimises the risk of damage when the clock is being transported. This sort of shock protection is generally only seen in wristwatches. In fact, Melchior’s exclusive table clock movement features the same type of mechanisms as a wristwatch – gear train, mainspring barrel (here five, in series), balance wheel, escape wheel and anchor – but their dimensions are far larger.

The movement also features superlative fine finishing – Côtes de Genève, anglage, polishing, sand-blasting, circular and vertical satin finishing – that is seen on a wristwatch. However, finely finishing a clock movement is far more challenging than finishing a wristwatch because of the greater surface areas of the larger components. L’Epée CEO Arnaud Nicolas explains:

“It’s not simply a case of double the size of the components, double the time it takes to finish them. The complexity increases exponentially. For polishing, for example, you need to apply the same pressure as when finishing a watch movement but on a bigger surface. Any variation in that pressure will show up in the finishing, so a skilled and steady hand is required to apply uniform pressure.”

The story behind the name “Melchior” is quite interesting as it is rooted in history of the Büsser family. Max Büsser explains:

“In the Büsser family, for over five centuries from the 1400s onwards, every eldest Büsser son was either called Melchior or Balthazar. It alternated. My grandfather was called Melchior and hated it, so he had everybody call him Max, which is how I became a Max. My grandfather hated the Melchior-Balthazar thing so much that he put an end to this 500-year-old tradition by calling my father Mario… Now, a century later, I happen to love the name Melchior!”

Technical specifications

Display

Jumping hours and sweeping minutes: Twin discs forming part of Melchior’s breast plate, one disc displaying hours, the other disc minutes, both featuring MB&F’s signature numerals

Retrograde seconds: Flyback discs mark 20-second intervals behind a steel mask

Power reserve indicator: Dial on abdomen providing intuitive view of remaining energy

Movement

L’Epée in-house designed and manufactured movement

Balance frequency: 18,000 bph / 2.5Hz

Barrels: 5 in series

Power reserve: 40 days

Movement components: 334

Jewels: 50

Incabloc shock protection system

Mechanism in palladium-plated brass

Manual-winding: double-depth square socket key sets time and winds movement

Movement finishing: includes Côtes de Genève, anglage, polishing, sand-blasting, circular and vertical satin finishing

Body and armour

Dimensions: 30.3cm x 21.7cm (depending on position of the arms) x 11.2cm

Weight: 6.3kg

Body/armour components: 146

HEAD

Dome: polished glass screwed via polished and bevelled palladium-plated brass bezel

Retrograde seconds display in stainless steel

Movement mainplate in palladium-plated brass

TORSO

Breastplate (forming hour and minute hands) in palladium-plated brass

Abdomen (power reserve indicator frame) in stainless steel

Ribcage/spine (formed by skeletonised mainplate) in palladium-plated brass

LEGS

Pelvis, thighs, shins and feet in stainless steel

Hips (long central bars joining pelvis) in stainless steel

SHOULDERS AND ARMS

Shoulders, upper arms and lower arm sockets in stainless steel; magnet in left arm socket

Right forearm: screwed-in rocket with chrome-plated brass body and stainless steel warhead

Left forearm: Gatling gun/detachable stainless steel winding key with palladium-plated brass

Body and armour finishing includes anglage, mirror polishing, satin finishing, circular satin finishing, sand-blasting, polishing. ‘Shoulders’, ‘pelvis’ and skeletonised mainplate treated with black PVD for the two-tone ‘dark and light’ edition of Melchior

Melchior is limited to 99 pieces

For more about Maximilian Büsser & Friends, go to www.mbandf.com, while to learn more about L’Epée 1839, go to www.lepee-clock.ch